Planning a woodworking project can be tough, mainly when figuring out material costs. A lumber cost estimator is a great tool. It helps both DIY fans and pros to know their project’s cost before starting.

Using a project estimation tool helps avoid going over budget. It lets you figure out lumber and material costs. This way, you know the total cost of your project.

A DIY project cost calculator helps you make smart choices. You can adjust your plans to match your budget. This saves time, money, and reduces stress.

Why Estimating Lumber Costs Is Critical for Project Success

Getting the lumber costs right is key to a successful woodworking project. It lets woodworkers plan and budget well, avoiding unexpected expenses later.

A good lumber cost estimation helps make smart choices about the project’s size and scope. It keeps the project within the woodworking budget, leading to project success.

Using a lumber yard pricing tool makes cost estimation more accurate. This tool gives current prices, helping woodworkers include material costs in their plans.

By focusing on accurate lumber cost estimation, woodworkers can finish projects on time and within budget. This boosts project success and builds a solid reputation for reliability and skill.

Lumber Cost Estimator: Price Your Project Before You Cut

Getting the right price for your project is easy with a lumber cost estimator. This tool lets you figure out material costs before you start cutting. It helps you keep your budget in check.

A lumber cost estimator looks at several things like lumber type, how much you need, and its size. It gives you a precise cost estimate. This way, you can avoid unexpected expenses and make smart choices for your project.

For both DIY fans and pros, a lumber cost estimator is a must-have. It aids in planning and lets you compare prices from different suppliers. This ensures you get the best value. Plus, thinking about how to store lumber can help save money by reducing waste.

Going for a woodworker aesthetic means your project will be both useful and look great. By knowing lumber costs, you can manage your resources well. This makes sure your project is a success.

In short, using a lumber cost estimator is key in planning any woodworking project. It helps you set a fair price, making your project run smoothly and look professional.

5 Types of Lumber Cost Estimation Tools

Choosing the right tool for estimating lumber costs is key to a successful project. Woodworkers have many options to make their work easier. Each tool has its own benefits for different needs.

Spreadsheet-based calculators are a common choice. They let users input details like lumber size, price, and amount. This method is popular because it’s flexible and can be customized.

Cost estimation software for woodworking is another favorite. These programs have lumber price databases and can calculate costs automatically. For example,

Online lumber price calculators are also popular. They let users quickly estimate costs by entering project details. They’re great for one-time projects or those who don’t need complex features.

Woodworking shops benefit from integrated inventory management systems. These systems track lumber stock and update costs automatically. This makes estimating easier and more efficient.

Mobile apps for woodworkers offer a convenient option. These apps can be used on-site to estimate costs quickly. They often include calculators and project planners.

Essential Information You Need Before Using an Estimator

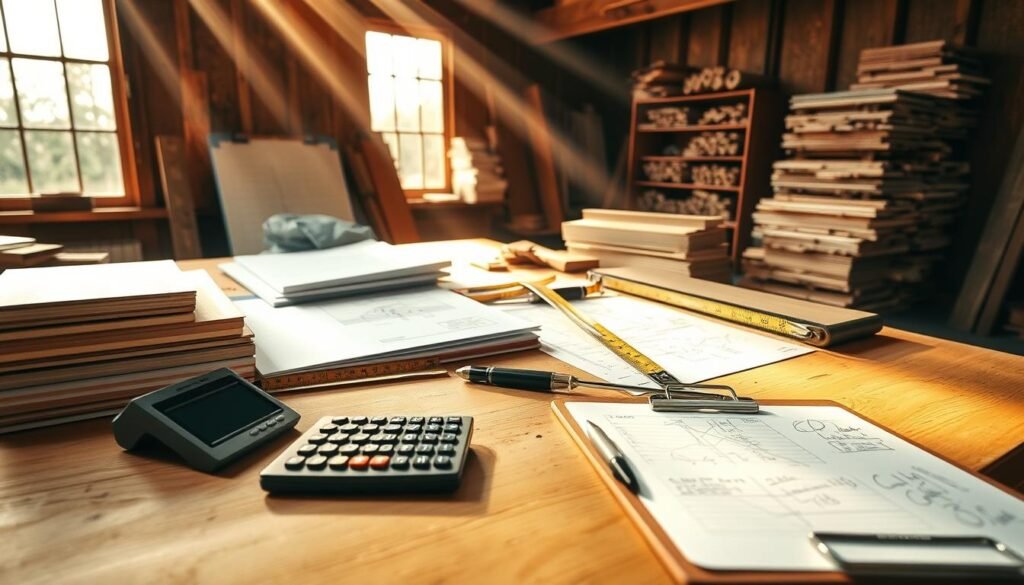

To get the most out of a lumber cost estimator, you need to be prepared. You should have specific project information ready. This includes detailed measurements, the type of lumber required, and any specific woodworking plans or designs you’re using.

Having accurate project details on hand is key. It ensures your lumber cost estimation is as precise as possible. This is very important for complex projects with many wood joints or custom designs.

Standard Waste Percentages by Project Type

Different projects have varying waste percentages. This is due to factors like design complexity and lumber type. For example, a simple shelving unit might have a waste percentage of around 10%.

On the other hand, a complex furniture piece with many cuts could have a waste percentage of 20% or more. Understanding these waste percentages is vital for accurate lumber cost estimation.

By knowing the expected waste, you can better plan your project budget. This helps avoid unexpected expenses. Whether you’re using SketchUp for your woodworking plans or working from detailed sketches, knowing the standard waste percentages for your project type is important. It helps you make more informed decisions.

Step-by-Step Guide to Calculating Your Lumber Needs

To keep your woodworking project affordable, you must accurately calculate lumber needs. This involves several important steps. These steps help you figure out exactly how much lumber you need, reducing waste and costs.

The first step is to measure your project’s dimensions. You need to know the length, width, and thickness of each part. For example, when making a shelving unit from poplar plywood, measure each shelf and the frame’s dimensions.

With your measurements in hand, calculate the total lumber volume needed. Multiply each component’s dimensions and add them together. Remember to add extra for waste, like when using shou sugi ban that might need more material.

After figuring out the total volume, think about the lumber type and availability. This helps you adjust your order if needed. By following these steps, you’ll have just the right amount of lumber for your project without buying too much.

Common Mistakes to Avoid When Estimating Lumber Costs

Even experienced builders can make mistakes when estimating lumber costs. One big error is not listing all materials needed for a project. This can cause budget overruns and delays.

Another mistake is overlooking the aesthetic value of lumber. The quality and look of the lumber can greatly affect the cost and project outcome.

To avoid these errors, make a detailed list of materials. Consider all factors that might change the cost, like lumber type and quality. Using a lumber cost estimator can help make this process easier and more accurate.

By knowing these common mistakes and how to avoid them, builders can keep their projects on budget and on time. They can also achieve the desired look, whether it’s a log or timber aesthetic.

Smart Lumber Storage Solutions to Reduce Waste and Costs

Effective lumber storage solutions can cut down on waste and costs. A well-organized storage system keeps your workshop tidy. It also makes it easier to find what you need.

Building a DIY firewood rack outdoor is a great idea. It keeps your workshop clean and protects your lumber from the weather.

For cedar wood projects, use a dry storage area to avoid warping or rotting. You can also look into backyard storage ideas to make a useful space.

By using these smart storage solutions, you can reduce waste, lower costs, and enhance your woodworking experience.

Conclusion: Build Confidently with Accurate Cost Estimation

Accurate cost estimation is key to a successful woodworking project. A good lumber cost estimator helps avoid surprises and keeps your project on budget. This lets you build with confidence, knowing the costs are clear.

Good woodworking shop and garage organization also cut costs and waste. Smart storage solutions make your workspace better and boost your productivity.

Now you can tackle woodworking projects with confidence. Use accurate cost estimation and efficient organization to create top-notch projects. Start building confidently today with the right tools and a well-organized workspace.